GET-Designs.uk

Designing Air Weapons since 1994 in the heart of England

RFD No 55/00000002542

* 3D Models.

* CNC Produced, Prototypes.

* Detailed production drawings.

* Assistance with manufacturing techniques and tooling.

* Ongoing Technical assistance and product development.

Graham Trim said on the 2024-03-26 16:01:47

Nimrod Air Gun 2024

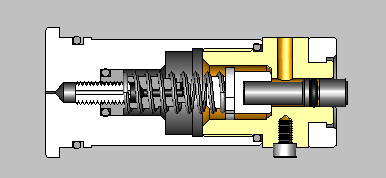

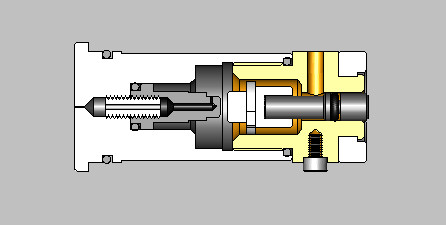

Early in 2003 I was approached by a company who wondered if it would be possible to have an air rifle specifically made for them. It took me around 12 months to come up with a unique design and produce a suitable prototype. Furthermore, when I designed this rifle there were noises from the powers that be, that they were looking into air weapons with a view to limiting, licensing or worse. So, I designed this one to comply I.E. it was not capable of being put over the legal limit of 12 ft/lbs using the sort of tools any reasonably competent D I Y person could do. As it turned out, I was the only one to do it to this degree. I designed valves that were limited by volume as can be seen from the sketches showing the valve in the open and closed conditions (the spring has been removed on the open version to show inlet air flow) and that is how I made it suitable for both .177 and .22 as the volume was specific to the calibre. Anyone wanting more information on the valves, can click on the link below the pictures, to see our explanatory video.

The firing pin has a built in O ring seal and acts like a piston so as soon as the valve is opened there is a force of around 50 kg trying to prevent it opening further and therefore the old idea of just increasing hammer weight or spring pressure had little or no effect. In this way I was able to accurately control power of my rifles and stop anyone altering them. It did not make me very popular, but I was happy that I was at least not open to danger of prosecution by the law as I was only a small company. You will notice that the air comes into the valve from the base via an accurately produced jet, this is used to create the pressure drop that allows the valve to close at the desired time and precisely control air usage. The time taken to develop was largely due to the fact it had to be a unique design that was relatively easy to make, in order to keep manufacturing costs low. However, by this time the company who wanted it, had changed their minds and were going to spend the earmarked money on increasing fishing tackle stocks. Whilst they had given me £1000 towards costs this in no way paid for my time, which is why I decided to go ahead and make it myself. Having spoken with a local manufacturing company, we decided that they would produce the major parts and I would make the Stocks, do the assembly and sell them, we would then split the profits between us. Whilst in theory this sounds like a good relationship, in practice what happened was that the manufacturer got busy and the job for which they are not getting paid for immediately, was put on the back burner. Therefore after a period of over 12 months with insufficient parts being produced, by mutual agreement we called it a day. At this point we had made only 28 rifles and the equipment and tooling went into storage. However, one night a group of undesirable individuals broke in and stole all of the tool boxes which were bright red Snap-On ones and most of the equipment to sell as scrap metal. Fortunately, there were no Air weapons or parts in that store because anything that could have been used had been assembled and sold. Whilst the Police specialist that investigated the case also estimated the value of the lost items to be over £30,000 and we knew exactly who had taken them, but since there never was any prosecution it was impossible to make any form of claim.

As the name suggests, Nimrod was designed as a light weight hunting air rifle, it is an extremely accurate and well-made single shot rifle with a rotary breach, however it is probably fair to say that it is a bit of a MARMITE item which is not liked by everyone. We know that those who have one very rarely part with them and many years later, I still quite frequently get stories of when and where they are used, and the results obtained. There is a video of Mario using his rifle in Malta, in the Media section on this site.

Over the following years due to the number of enquiries, I did replace some of the lost tooling and make a few new rifles for customers in the UK.

Back in 2020 I had a request to produce rifles for a gun shop in Malta but as we were nearing the completion of the first batch BREXIT happened and it is now not economical to send them out.

Parts were made for 4 but the rifles were not assembled because if they had have been, they would be FAC rated and then not suitable for sale over here.

Currently I have parts to build One .177, One .22, One .20 and one .25 However I could make all 4 in .177 or .22 if that was required. They will be sold on a first come first sold basis and limited to under 12 ft/lbs. Since they are hand-made they will be more expensive than standard off the shelf rifles and each one assembled to order. If these fly off, of the shelf, then a few more may be built, but only to use up the remaining spare parts in stock. However as each item is used up and more of the missing components have to be hand-made, then it becomes less viable to produce complete rifles in this way. Therefore, this will always be a very rare rifle with less than 50 ever made.

Whilst so far, only 31 have been made, they do seem to be owned by customers in several different countries many of whom stay in touch. There are a couple of rudimentary videos in the Media section of this site, for anyone that wants to carry out simple servicing such as changing the Orings, that are most likely to require replacing, after a number of years of use.

We are making the latest version of this rifle available via the Shop section of this site, but here in the UK, we have to sell either direct by face to face contact with the customer, or RFD to RFD. So if you really are interested in purchasing one of these very rare rifles, then in the first instance, please email me via graham@get-designs.uk .

Optional Alternative Rotary Cocking Device.

During the high-power Export development process, it was necessary to increase the valve dimensions to meet the performance requirements, this required the use of a stronger hammer spring which in turn increased the pull load required to cock the rifle. A new rotary tensioning system was designed to accommodate the extra loads encountered. This utilized a fast leadscrew, to draw the leaver back using around one half of a turn of the new style PEEK handle. PEEK was used in this application to provide the tortional strength required and in the natural form is pale brown, but it is looking lighter here because the light is reflecting off of it.

The video shows how this would be used. It shows the rifle hammer being armed and fired followed by it being armed and then the hammer being let down into the safe position without firing the rifle.

Existing .177 Nimrod rifles do require more effort to tension than current .22 versions, due to a heavier hammer spring being used in manufacture. If anyone wanted to use this system, it can be retrofitted to existing rifles which does make them much easier to prime, but they would need to come back for updating.

During testing it became apparent that the high-power valves could not be de-tuned to work within the sub 12 ft/lb limit and give an acceptable power curve. Therefore, the New sub 12 ft/lb Nimrod rifles now being offered for sale, have been fitted with an improved updated valve system that does not require the heavy hammer spring, and therefore will be much easier to cock and fire. furthermore, a major advantage of this new improved valve, is that the rifle is now substantially quieter at the muzzle than all of the predecessors, without a silencer fitted.

Anyone wanting a high power version of this Nimrod rifle and prepared to have it put onto their Firearms Certificate should get in touch as indicated above.

More in the series ...

From Humble Beginnings

The story behind the making of my first ever PCP.

Whirlwind CNC Rifling Machine

Reaper Development Trail

Paradigm Development part 3

Paradigm Development part 2

Paradigm Development part 1

Twin Opposing Piston Spring Rifles Preface

3D Printing And Air Weapon Development

Innovate to Thrive

Velociraptor project

Fox Rifle Dynasty

Observations regarding the Webley MkII Service Rifle